POLYURETHANE CONCRETE LEVELING/RAISING

Since 2014 we have been partnered with over 1000 home owners and commercial clients to help them raise/level their concrete flatwork. All our customers can expect outstanding customer service with excellent communication throughout the project. They have relied on us to continuously go above and beyond to provide accurate, and honest concrete raising and leveling and foundation repair.

We love our customer, which is why over 50% of our new customers come from past customer referrals.

A quicker, easier and more cost-effective choice than replacing your concrete.

Concrete replacement can cost over $20/sqft and take a week/s to complete. Foam injection can be less than $10/sqft and completed in hours not days. Don’t endure the pain, inconvenience and cost of concrete replacement; choose polyurethane foam injection leveling. When arrive for a free consultation, homeowners are often ecstatic to learn they can have perfectly aligned concrete again, in matter of minutes, saving time and money. Process is excellent for commercial or residential projects and is Municipality, GSA, DOT, HOA, OSHA, etc approved. Some common areas we level and are ready for immediate use; patios, driveways, pool decks, garage/parking slabs, steps, parking lots, warehouse floors, roadways and much more!

Concrete raised, leveled and repaired using polyurethane foam is often ready to sustain normal use within minutes of being leveled.

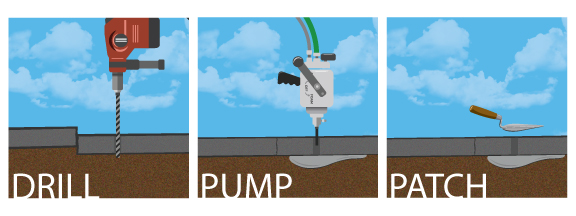

How does Polyurethane foam concrete raising work?

Great question! Firstly, we believe it’s good for you to know that most concrete raising jobs will take between one to two (1-2) hours—start to finish—and your concrete will be ready for use immediately upon completion!

- When you level your uneven concrete using poly foam concrete raising techniques, ⅝” injection holes (Size of a dime!) are strategically drilled around the areas where the concrete is sunken and requires lifting.

2. The concrete raising equipment is contained in our custom trailer, and has a sufficient length of hose to accommodate most locations, the hose is extended to reach the area in need of repair

3. Once everything is prepped and the hose and materials are in place, the polyurethane foam is injected through the holes which fills the space underneath the concrete slab, using the concrete slab itself to drive the foam into the crevices, thereby lifting the concrete back to its original, correct level

4. Upon completion of leveling the concrete, the injection hole(s) are filled discretely with new cement, allowing you to use your surface immediately.

It’s as simple as drill, pump and patch! Your concrete is ready to use immediately!

Benefits to raising concrete with polyurethane foam

While there are many benefits to using Mr. Sidewalk specializing in polyurethane concrete raising, here are a few that we find to be the most important:

- Polyurethane foam concrete raising is more cost effective than replacing your concrete slabs

- Since slabs are leveled and not replaced, the color, finish and texture of leveled slabs will match existing unleveled concrete. (NEW concrete never matches OLD concrete)

- Raising concrete with poly foam often takes a couple of hours and is ready immediately upon completion, as compared to hours or days for new concrete replacement

Poly VS Mud Jacking

Both methods of concrete lifting will achieve the same results. Those results are achieved in dramatically different ways. Mudjacking and Poly Leveling concrete will raise and support sunken or unstable concrete slabs by drilling holes and pumping material under the slab.

Site Cleanliness: Poly WINS!

Polyurethane is a completely self-contained system. Poly material is held in a drum pumped through reactor, hoses and directly under the concrete. No heavy carts are driven through your lawn. Poly is only pumped when foam gun valve is opened. Therefore concrete/street/lawn does not need to be washed after leveling.

Mud uses a sand based material that is infused with Portland cement that is mixed on site, transferred to power cart to work area than pumped under slab. As with concrete replacement this Mud gets everywhere and must be washed off before staining your slabs. The heavy power cart can leave tire tracks in your yard from trailer to work area.

Material Constancy: Poly WINS!

Polyurethane comes from Manufacture with MSDS available. The mix is the same every time. This constancy translates to a better and longer lasting repair. This accuracy of materials and laboratory properties is why poly is the only DOT approval leveling material.

Mud is a mixture of sand based material that is infused with Portland cement. It comes from different suppliers and different sources with not data or material list included. Then is mixed by shovel on the trailer. The final material is different ratio in every batch. If the leveling Mud changes then the long-term performance is always changing.

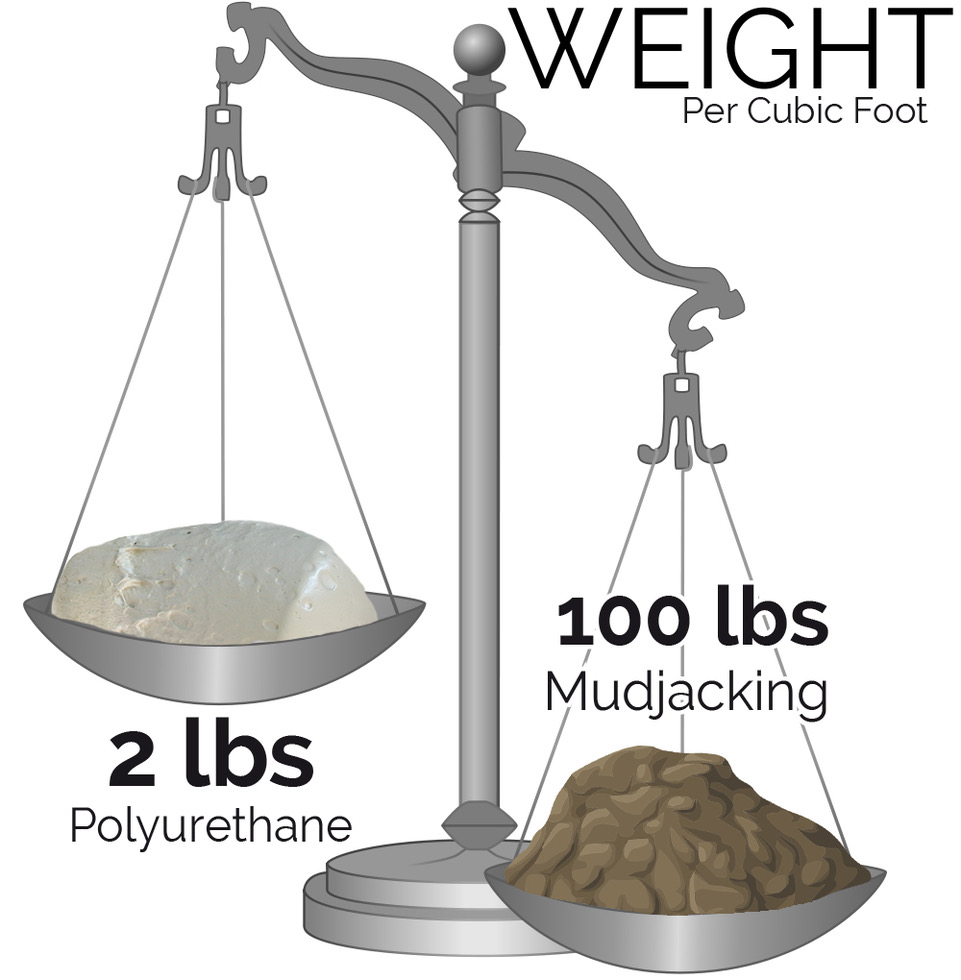

Material Weight: Poly WINS!

Polyurethane has become a popular repair method because the material is so lightweight (2-4lbs/cuft), it will not further burden the already weak soil.

Mud uses a sand based material that is infused with Portland cement. This slurry is hydraulically pumped under the slab to fill voids and raise the concrete. Mud material weighs on average 100 lbs/cuft.

Settled concrete is commonly a result of poor soil conditions beneath a slab. Don’t add more weight to poor soil. It can make mater worse.

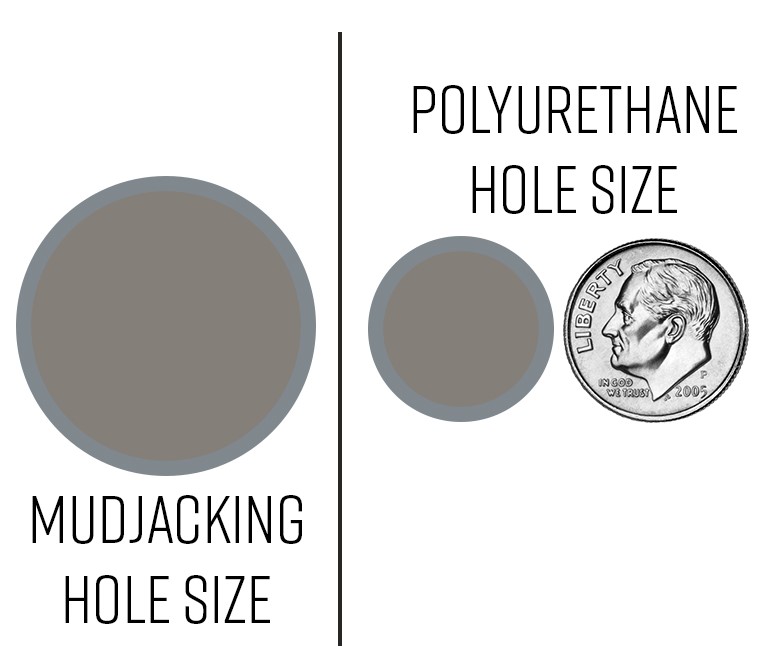

Hole Size: Fewer and Smaller: Poly Wins!

After the slab has been raised, the only visible evidence that the concrete has been repaired are the holes. For this reason, polyurethane has gained HUGE popularity because of the nearly invisible 5/8″ holes that remain after the job is completed.

Mudjacking involves drilling a series of 1-5/8″ holes in a slab of concrete, so the material can be pumped under the settled slab.

Polyurethane concrete raising drills a nearly invisible 5/8″ hole and the process calls for considerably fewer holes than traditional mudjacking.

Investment / Cost: Mud WINS!

Concrete raising is typically half the cost of replacing your concrete slab. When large voids are present, this can increase the cost of the repair. While polyurethane material is more expensive than mudjacking material, the smaller hole size, lighter material weight, and fewer injection holes, make the investment in polyurethane over mudjacking well worth it.

We have saved our customers millions of dollars, versus if they would have replaced their concrete.

Mr. Sidewalk of Houston

(713) 532-2300

US Military Veteran Owned and Operated. Content copyright Mr. Sidewalk. All rights reserved.

Professional Uneven Sidewalk Raising and Walkway Leveling and Raising Repair Services in the following areas:

Alief, Atascocita, Bellaire, Clear Lake, Conroe, Lake Conroe, Downtown, First Colony, Greatwood, Houston, Heights, Humble, Katy, Kingwood, League City, Magnolia, Memorial, Meyerland, Midtown, Missouri City, Montrose/Neartown, New Territory, Pearland, River Oaks, Richmond, Sienna Plantation, Spring, Stafford, Sugar Land, Tanglewood, Tomball, The Woodlands, and West University.